Call us now: 01123860572

INCOL Fire Survival Cables

Need of ensuring safe operation of critical circuits is essential in today’s installations. Normal cables used in such installations render useless in fire incidences. At INCOL, your safety is our concern. INCOL has now developed special type “Fire Survival Cables” through research. These cables - also known as CIRCUIT INTEGRITY CABLES & are designed to sustain the high temperatures for a defined minimum period of time under direct fire. These cables are useful to maintain their integrity during the defined period of fire. The construction of these cables is different if compared with ordinary cables. The conductor is manufactured with a specially designed heat barrier and fire resistant insulation which resists the fire to reach conductor surface. The cable continues to remain into operation at high temperatures like 650°C, 750°C and 950°C as per various conditions of operation and applications.Wires offering same properties are also available. These cables are manufactured and tested in accordance with BS 7846, IS 7098(P-1), IEC 69331 and BS 6387 for required temperatures and duration - depending upon the application of cable and site conditions.

Designed For Critical Installation Of National Importance Like

| • Airports |

| • Metro Rail Projects / Rail Terminals |

| • •Nuclear / Thermal Power Plants |

| • Installation Prone to Fire |

| • Interstate Bus Terminals |

| • Introduction |

Constituents :

| 1. Annealed Plain Copper Conductor |

| 2. Heat Barrier Over The Conductor |

| 3. Cross Linked Polyethylene |

| 4. Galvanised Steel Armour |

| 5. Zero Halogen & Low Smoke Compound |

The ZHLS compound ascertains the least smoke and hence increased light transmission during burning of cables. The circuit integrity of FIRE SURVIVAL cables at high temperatures remains unaltered for the required time period as per the specification defined.

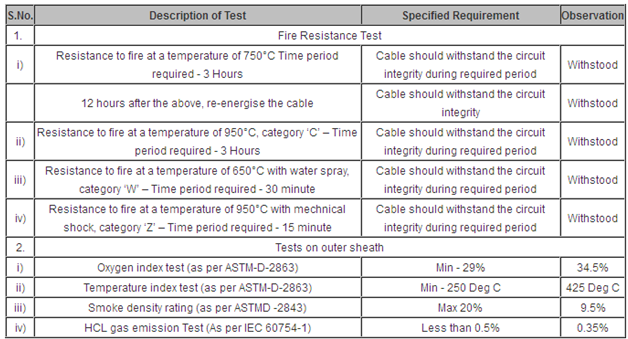

Test Requirements:

| 1. Fire Resistance Test |

| 2. Smoke Density Rating |

| 3. Halogen Gas Emission Test |

| 4. Oxygen Index Test |

| 5. Flammability Test As Per Swedish Chimney |

Special Properties:

| 1. Circuit Integrity under fire at high temperature |

| 2. Enhanced Current Carrying Capacity due to high permissible conductor temperature |

| 3. Higher Short Circuit Capacity |

| 4. Lighter in weight hence easy to handle and installation |

| 5. Reluctant to Overheating |

| 6. High Oxygen Index – refrains the cable from spreading the fire |

| 7. Low smoke density reduces the environmental opaqueness during fire |

| 8. High degree of light transmission in the event of fire |

| 9. No chance of emission of Halogen Gases – safe for humans |

| 10. Negligible emission of Toxic and Corrosive gases - diminishing the chance to damage the human body/sensitive equipment |

Circuit Integrity (Fire Resistance) Test : as per IEC 60331

The test is carried out on the cable operational on load and burning at a temperature of 750 Deg C for 3 hours. The cable is put on the clamps above the fire burner of high flames. The power supply is connected to one end of cable at rated voltage and the load is connected to other end. Fire applied for 3 hours and during this period, the circuit integrity must be uninterrupted. After the 3 hours, the fire and power is switched off. The cable should report as usual when energised again after a gap of 12 hours.

Our Products

- Incol Instrumentation Cables

- Incol Telephone Cables Internet Compatible

- Incol Single Core/Hook-Up Wire

- Incol Thermocouple Cable

- Incol Twin Cord Speaker Cable Systems

- Incol Coaxial Cables

- Incol House Wiring Cables

- Incol Power Cord Systems

- Incol Battery Cable

- Incol Rubber Cables

- Incol Submersible Cables

- Incol Welding Cables

News Highlight

- Polytetrafluoroethylene (PTFE) is a synthetic high molecular weight solid state fluorocarbon consisting largely of carbon as well as fluorine atoms.

- The company offers a broad range of continuous filament yarns and performance-enhancing coatings for the packing market.

- Diameter Multipliers for Round Core Cables

- The wire size calculator will give you a very simple and quick solution to the problem of calculating the size of wires and cables for pump applications in golf courses, landscape projects, and agriculture.